MoS2

Copolyoxymethylene

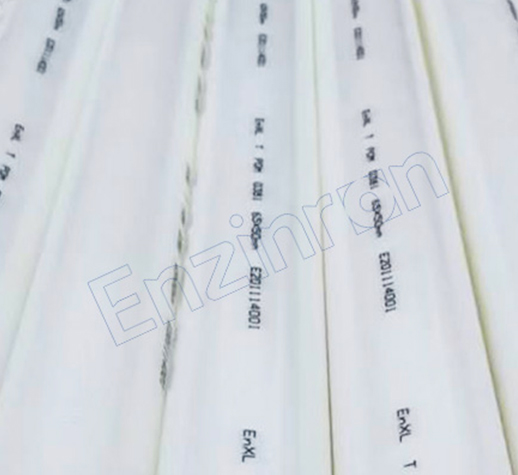

Polyformaldehyde (POM) adding molybdenum disulfide wear-resistant particles mixed extrusion of a special wear-resistant engineering composite material, the material is more wear-resistant than pure POM.

Advantage

Characteristic:

Super wear resistance, high mechanical strength, good dimensional stability, good self-lubrication performance, high surface hardness.

Information

| Shape | Colour | ||

|  | ||

| Plate | Bar | Black | White |

| Thickness(mm) | Breadth(mm) | Length(mm) |

| 0.5-100 | 610/1000 | 1220/2000 |

| Diameter(mm) | Length(mm) |

| 6-100 | 1000/2000 |

Specific gravit | ASTM D792 | g/cm3 | 1.46 |

Tensile yield strength | ASTM D638 | Mpa | 64 |

Breaking elongation | ASTM D638 | % | 20 |

Bending strength | ASTM D790 | Mpa | 84 |

Flexural modulus | ASTM D790 | Mpa | 2800 |

Shore hardness | ASTM D2240 | D | 85 |

Impact strength | ASTM D256 | J/M | 50 |

Melting point | DSC | °C | 190 |

Heat distortion temperature | ASTM D648 | °C | 130 |

Operating temperature | - | °C | 100 |

Maximum operating temperature | - | °C | 150 |

Thermal conductivity | DIN 52612-1 | W/(K-M) | 0.33 |

Coefficient of linear themal | ASTM D696 | 10-5-1/K | 1.3 |

Dielectric strength | ASTM D150 | KV-mm | - |

Dielectric loss factor | ASTM D150 | - | - |

| Volume resistivit | ASTM D257 | Ω.cm | 1014 |

Surface resistivity | ASTM D257 | Ω | 1016 |

Dielectric constant | ASTM D149 | - | - |

| Water absorption | 23°C 60%RH | % | 0.5 |

Acid resistance | 23°C 60%RH | + | |

Alkali resistance | + | ||

Acid and alkali resistance | + | ||

Resistance to sodium chlorate | 0 | ||

Resistance to aromatic compounds | + | ||

Resistance to ketone | 23°C 60%RH | + | |

Resistance to hot water | 23°C 60%RH | + |

Flammability | UL 94 | HB | |

Viscosity | - | + | |

Non toxic | EEC 90/128 FDA | + | |

Coefficient of friction | DIN 53375 | + | |

Anti-ultraviolet | - | 0 |

Related product recommendations

-

Available profile types

-

plate

-

Bar

Available profile colors

-

white

-

Black

-

Green

-

Gray

-

Yellow

-

Red

-

Blue

-

Orange

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

white

-

Black

-

Brown

-

Dark brown

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

Black

-

cream-coloured

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

White

-

Black

-