POM+PTFE30%

Copolyoxymethylene

POM+PTFE30% is a blend of POM and Teflon material, which retains most of the strength of POM. Due to the change of material properties after adding Teflon, the material becomes softer, less rigid, and the surface becomes smoother.

Advantage

Characteristic:

1. Low friction coefficient, wear resistance, and basically no creep phenomenon, good creep resistance; Even at low temperatures, the impact strength is high.

2. Very good dimensional stability; The sliding property is better than pure POM, and the mechanical property is excellent. Physiological inertia, suitable for contact with food.

Information

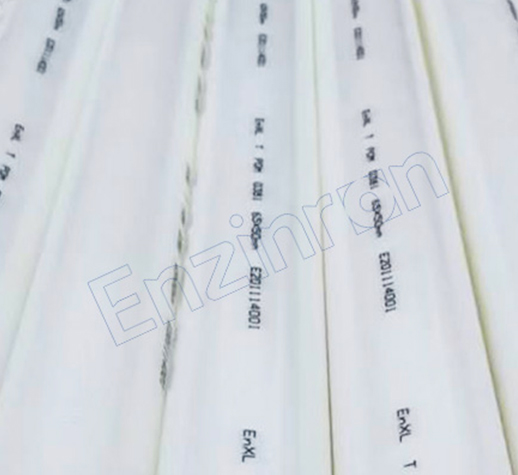

| Shape | Colour | ||||

|  | ||||

| Plate | Bar | White | Coffee Color | Black | Dark Brown |

| Thickness(mm) | Breadth(mm) | Length(mm) |

| 6-100 | 610/1000 | 1220/2000 |

| Diameter(mm) | Length(mm) |

| 6-200 | 1000 |

Specific gravit | ASTM D792 | g/cm3 | 1.5 |

Tensile yield strength | ASTM D638 | Mpa | 55 |

Breaking elongation | ASTM D638 | % | 30 |

Bending strength | ASTM D790 | Mpa | 80 |

Flexural modulus | ASTM D790 | Mpa | 1700 |

Shore hardness | ASTM D2240 | D | 80 |

Impact strength | ASTM D256 | J/M | 40 |

Melting point | DSC | °C | 175 |

Heat distortion temperature | ASTM D648 | °C | 130 |

Operating temperature | - | °C | 100 |

Maximum operating temperature | - | °C | 150 |

Thermal conductivity | DIN 52612-1 | W/(K-M) | 0.31 |

Coefficient of linear themal | ASTM D696 | 10-5-1/K | 10 |

Dielectric strength | ASTM D150 | KV-mm | 19 |

Dielectric loss factor | ASTM D150 | - | 0.007 |

| Volume resistivit | ASTM D257 | Ω.cm | 1014 |

Surface resistivity | ASTM D257 | Ω | 1016 |

Dielectric constant | ASTM D149 | - | 3.6 |

| Water absorption | 23°C 60%RH | % | 0.26 |

Acid resistance | 23°C 60%RH | + | |

Alkali resistance | + | ||

Acid and alkali resistance | + | ||

Resistance to sodium chlorate | 0 | ||

Resistance to aromatic compounds | + | ||

Resistance to ketone | 23°C 60%RH | + | |

Resistance to hot water | 23°C 60%RH | + |

Flammability | UL 94 | HB | |

Viscosity | - | + | |

Non toxic | EEC 90/128 FDA | + | |

Coefficient of friction | DIN 53375 | 0.35 | |

Anti-ultraviolet | - | 0 |

Related product recommendations

-

Available profile types

-

plate

-

Bar

Available profile colors

-

white

-

Black

-

Green

-

Gray

-

Yellow

-

Red

-

Blue

-

Orange

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

white

-

Black

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

Black

-

cream-coloured

-

-

Available profile types

-

plate

-

Bar

Available profile colors

-

White

-

Black

-